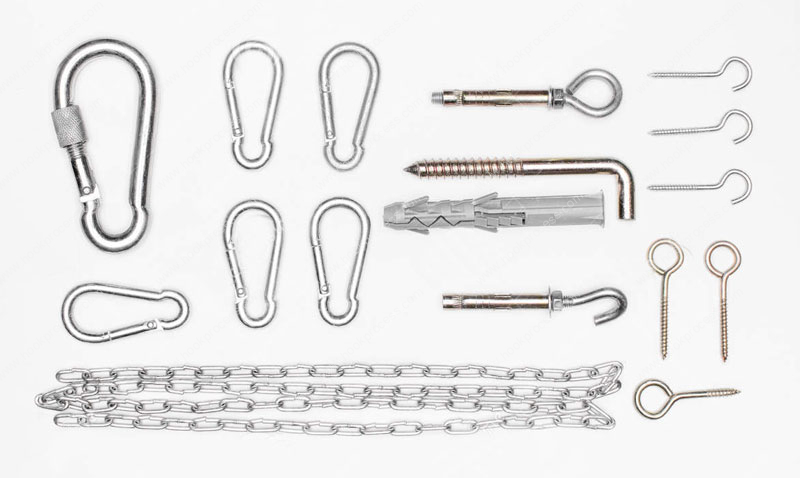

Different Type Wire Hook Introduction

A wire hook is a hardware component consisting of an elongated material containing a bent portion. This portion is used to hold, hang or clamp another object. For several purposes one end of the hook is pointed, so that end can pierce another material, which is then held by the curved or indented portion. Ends can be also rounded.

The parameter for defining a wire hook are type, length, wire diameter, and bend diameter.

Wire Hook Type Classification

Exist on the market countless models of hooks depending on their function. Then we name some of the more generic forms.

C-Wire Hooks

these hooks are ideal for wider parts or multiple styles of parts with varying thicknesses. C style hooks have rounded ends which permit easy placement on round profiles and crossbars. These hooks can be used in combination of Daisy-Chain multiple items together to suit the required length.

Wire hooks c product 1

S-Wire Hooks

these hooks are similar to C hook with the difference of his ends are bended on opposites sides. Metal S shape hooks have rounded ends specially design for hooking on the round pipe, rails or similar. It’s recommended that for maximum loading and repeated usage, ensure the product being hung seats into the bottom of the “C”.

Wire hooks s product 1 Wire hooks s product 2

V-Wire Hooks

the most characteristic feature of this hook is that it have a “V” shape that improve his ability to retain considerably longer than a C style hook. Also the “V” bottom allows the hung part to rest in the same location each time. Parts hung from these hooks show more stability on the line and will maintain better their orientation.

Wire hooks v product 1

J-Wire Hooks

this type of wire hook is a great all-purpose hook. It’s possible to see it on motorcycle straps, utility trailer straps, cable support systems, and many more ratchet strap applications.

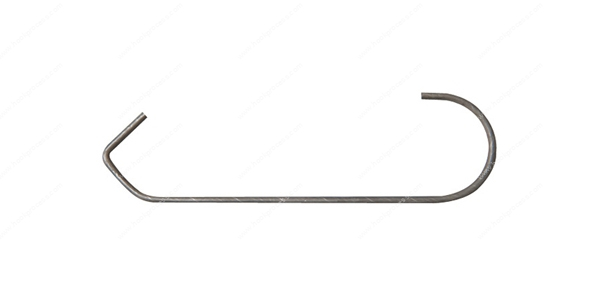

CV-Wire Hooks

this hook combines features of a “V” style hook and the ease of use of a “C” style hook. It can be used on both traditional, and round stock conveyor systems.

Wire hooks cv product 1

Utility Hooks

are hooks that are not designed for a specific application. For this reason exist a wide variety of them that can present different forms, threads, special coatings, etc. Some examples can be rubber rope hooks, hanger hooks, shelving hooks, etc.

Wire hooks utility product 1 Wire hooks utility product 2 Wire hooks utility product 3

In addition to the above-mentioned, Romiter provides other types of wire hooks machine for very specific applications. Some examples can be rubber rope hooks, hanger hooks, shelving hooks, etc.

Wire Hook Production

Romiter Machinery offers a complete line of custom wire hooks to meet the needs of any industry. We can produce hooks machine according to specific customer requirements because we have the necessary means to produce wire bending products with a wide range of wire diameters, hook forms, materials, surface coatings, etc.

Wire hooks production 1 Wire hooks production 2

TREATMENTS AND COATINGS

we offer a wide variety of finishes to satisfy customer needs.

Hooks are components which a correct heat treatment and coating is very important in order to the part can comply his function. We apply the necessary heat treatment according to material and client requirements.

The most extended coating for hooks is the vinyl coating, which gets more grip and great resistance to corrosion. According to with the material others, coatings can be applied to hooks such as:

- Electropolishing

- Tumbling

- Shot Peening

- Electroplating

- Electroless Plating

- Chemical Coatings

Hook Making Materials

Hooks can be produced from a wide variety of metals, but the most used for industrial purposes are:

- Carbon steel

- Stainless steel

- Brass

- Monel

- Aluminum

- Titanium

STANDARD AND CERTIFICATES

We have the means to ensure our products comply with the general regulation and the specific certificated regulations in manufacturing products that require them.

ISO 9001 and ISO 14001.

TS 16949.

OHSAS 18001.

Company Profile

Romiter Machinery Co., Ltd. is a market-leading designer and manufacturer of Hook Processing Machine. Romiter has an excellent technical support team. All our machines are equipped with reliable brand components. This enables us to provide our customers with continuous high-quality and state-of-the-art hook processing machines at competitive prices.

Romiter Group provides a complete Hook Processing Solution, which includes but is not limited to Hanger Wire Hook Making Machine, Double J-Lashing Hook Making Machine, Snap Hook Carabiner Making Machine, S-Shape Wire Hook Making Machine, Flat Wire Hook Making Machine, Metal Eye Hook Making Machine, Tomato Hook Making Machine, Aluminum Wire Hook Making Machine, Fish Hook Making Machine, Wall Row Hook Making Machine, Domestic Adhesive Wire Hook Making Machine, Rack Hook Welding Machine, Expansion Hook Making Machine, Ball Head Hook Making Machine, Swivel Snap Hook Assembling Machine, Magnetic Hook Assembling Machine, Metal Hook Packing Machine, Wire Straightening Cutting Machine

Romiter Hook Processing Machine meets Europe Quality Requirement with CE Certification