Different Snaps Hook Types Introduction

Snaps—also known as snap hooks or spring hooks—are hooks with a spring snap in their ends to prevent the accidental unhooking of a rope, cord, or other target line. Snaps are a common but essential component in a huge range of industrial applications, from dog leashes to theatrical lighting.

The Different Types of Snaps

With multiple snap types available, it may not be immediately clear which type is correct for a given application. This page will explore the different types of snaps and their applications.

The traditional snap hook is perhaps the most common type. Snap hooks are equipped with a durable spring that allows for strong, quick attachment to a rope, cable, chain, or other line.

In its most basic form, a snap hook is a roughly question-mark shaped metal hook with a hollow section into which the spring-loaded closing bar is fitted. There will also be a small appendage that catches the snap hook and opens it when pressed with the thumb. Upon release of the knob, the gate snaps close by the spring’s action.

Snap hooks can come from a wide variety of source materials, such as brass, stainless steel, and die-cast zinc. They also can provide different functions, such as:

Panic snaps. This snap type allows the attached rope or cable to be released almost instantly. Some panic snaps are specifically designed for horses and come with a ring that instantly releases anything attached to the snap.

Fixed-eye snaps. These snaps have bases that are fixed in place. They are often used in the marine industry as boating attachments.

All-purpose snaps. These snaps let the operator change lures/rigs quickly without the need to retie a line.

Swivel-eye snaps. Swivel-eye snaps have an adjustable base that allows the spring to turn along its vertical axis.

Snap Hook vs Carabiner

A carabiner is a metal loop with a spring-loaded entryway that will quickly open in order to detach a safety rig’s parts, such as the cable or line. The only way to open a carabiner is to manually push the gate away from the loop. This is one key difference between a carabiner and a more traditional snap hook—the snap hook can only release the cord or rope it holds if the spring gate is pushed towards the loop, instead of away from it.

Snaps vary in the amount of weight for which they are designed, and the amount of force they can successfully withstand without breakage. Snap hooks and carabiners should both have a kN (kilo-Newton) rating engraved on their spine. This is a rating for the force of gravity that the snap can successfully absorb.

Heavy-Duty Snaps

For certain applications, the use of heavy-duty snaps is imperative. These snaps are constructed for strength and durability, and are subject to rigorous American National Standards Institute (ANSI) guidelines.

For instance, ANSI requires that fall-protection hardware have at least a 16 kN rating for the gate, and a 22.5 kN rating for the tensile load. In other words, the snap’s spring gate should be able to withstand kN forces of 3,600 pounds, and the snap itself must handle forces of 5,000 pounds.

Trigger Snaps Hook

What are trigger snaps? Trigger snaps are considered a specialized type of snap hook. The distinguishing feature of a trigger snap is the addition of a small lever onto the spring gate apparatus. The snap’s user can easily press the lever, which then causes the spring gate to retract inwards and release the attached line. In practice, this means that a snap operator can easily attach or detach from a line with one hand.

Moreover, the trigger snap is designed so that it will not open accidentally. Trigger snaps are used for handbags and purses, camera and binocular straps, and other fashion or accessory applications.

Bolt Snaps Hook

Bolt snaps are like trigger snaps in the sense that they can be easily operated with one hand. The main difference between the two snap types is the unlocking mechanism. Whereas a trigger snap utilizes a lever; a bolt snap employs a button that causes the spring gate to release when pressed.

Bolt snaps tend to be less secure than trigger snaps since accidental pressure on the release button could cause an unintended detachment from the line or strap.

Applications: What are Snaps Used For?

Snaps can be used in a comprehensive array of industries and applications. Examples of common applications include:

Sports equipment. Snap hooks can keep volleyball and tennis nets level and tight. Facility managers for baseball fields may use them to hold up the netting behind home plate. Snap hooks may also be used to secure rifle slings, bird straps, or water skis. The sports applications for snap hooks are almost limitless.

Dog leashes. Dog leash snap hooks come in a wide variety and at different cost and quality levels. Factors to consider in choosing a snap hook type for dog leashes include: snap material, swivel-eye vs. fixed, eye shape, and eye diameter.

Awnings. Whether an awning is retractable or stationary, stainless steel snap hooks and other snap types typically provide stable and adjustable support.

Marine hardware. Sailors can employ snap hooks to attach to anchor chains, trailer safety chains, to secure equipment, or to secure vessels to docks.

But while snap hooks are usually thought of as heavy-duty hardware and associated with tough, durable products, the truth is that snap hooks have a softer side. There are many creative ways that snap hooks can be put to use.

Snap Hook Hardware Materials

There are five types of material commonly used to produce snaps. Each material has its own unique properties and advantages.

Die-cast Zinc Snap Hook

Zinc casting alloys tend to be stronger than reinforced, molded polymers. Zinc has self-lubricating abilities, and its stability makes it highly compatible for mechanical parts that move, such as gears. Zinc is also non-toxic and reusable.

Stainless Steel Snap Hook

Stainless steel is exceptionally resistant to corrosion, making it a good fit for outdoor applications. In fact, high-grade stainless-steel alloys are even compatible for high acidity, high pressure, and high temperature conditions. Stainless steel is extremely durable and its lifespan typically offsets any increased upfront costs.

Brass Snap Hook

Manufacturers often use brass for highly decorative applications that don’t involve a lot of moving parts or constant friction. Furthermore, brass is highly non-flammable, making it perfect for products that will be used around flammable or explosive gases.

Malleable iron Snap Hook

This material is often used for small castings or castings that have cross-sections of 0.25” or less. Malleable iron is very tough, highly ductile, and extremely heat resistant. It is utilized in electrical and pipe fittings, hand tools, and farm equipment, among other products.

Steel Snap Hook

Steel is a strong metal and can be formed according to rigorous standards of safety and quality.

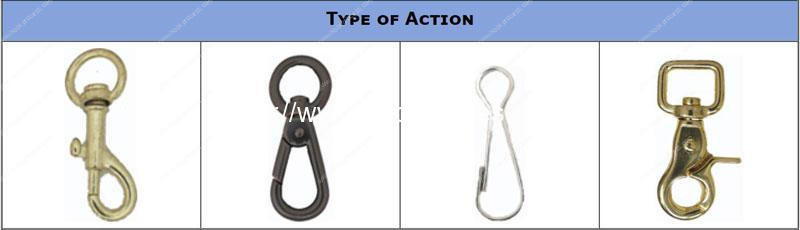

How to Separate Hook in Different Category

1. Separate According Opening and closing the Loop

| Bolt Snap Hook | Push Gate Hook | Spring Hook | Trigger Snap Hook |

2. Separate According to the Swivel Hook and Rigid Hook

| Swivel Snap Hook | Rigid Snap Hook |

3. Separate According to the Shape

We offer a variety of eye shapes (what the strap attaches to): rectangular or oval to accommodate flat straps of varying widths, and also round rings for smaller diameter straps, cords or other rings. All of our snap hooks can be specially designed to meet any specific needs that you have.

| Strap-style Eye (for wider straps) | Ring-style Eye (for narrow straps, cords and rings) |

While they may be small components, snaps are essential to many applications across diverse industries. It’s important that you match the right snap to your project to ensure its ultimate success. Hope you can get the Right Snap hook

Company Profile

Romiter Machinery Co., Ltd. is a market-leading designer and manufacturer of Hook Processing Machine. Romiter has an excellent technical support team. All our machines are equipped with reliable brand components. This enables us to provide our customers with continuous high-quality and state-of-the-art hook processing machines at competitive prices.

Romiter Group provides a complete Hook Processing Solution, which includes but is not limited to Hanger Wire Hook Making Machine, Double J-Lashing Hook Making Machine, Snap Hook Carabiner Making Machine, S-Shape Wire Hook Making Machine, Flat Wire Hook Making Machine, Metal Eye Hook Making Machine, Tomato Hook Making Machine, Aluminum Wire Hook Making Machine, Fish Hook Making Machine, Wall Row Hook Making Machine, Domestic Adhesive Wire Hook Making Machine, Rack Hook Welding Machine, Expansion Hook Making Machine, Ball Head Hook Making Machine, Swivel Snap Hook Assembling Machine, Magnetic Hook Assembling Machine, Metal Hook Packing Machine, Wire Straightening Cutting Machine

Romiter Hook Processing Machine meets Europe Quality Requirement with CE Certification